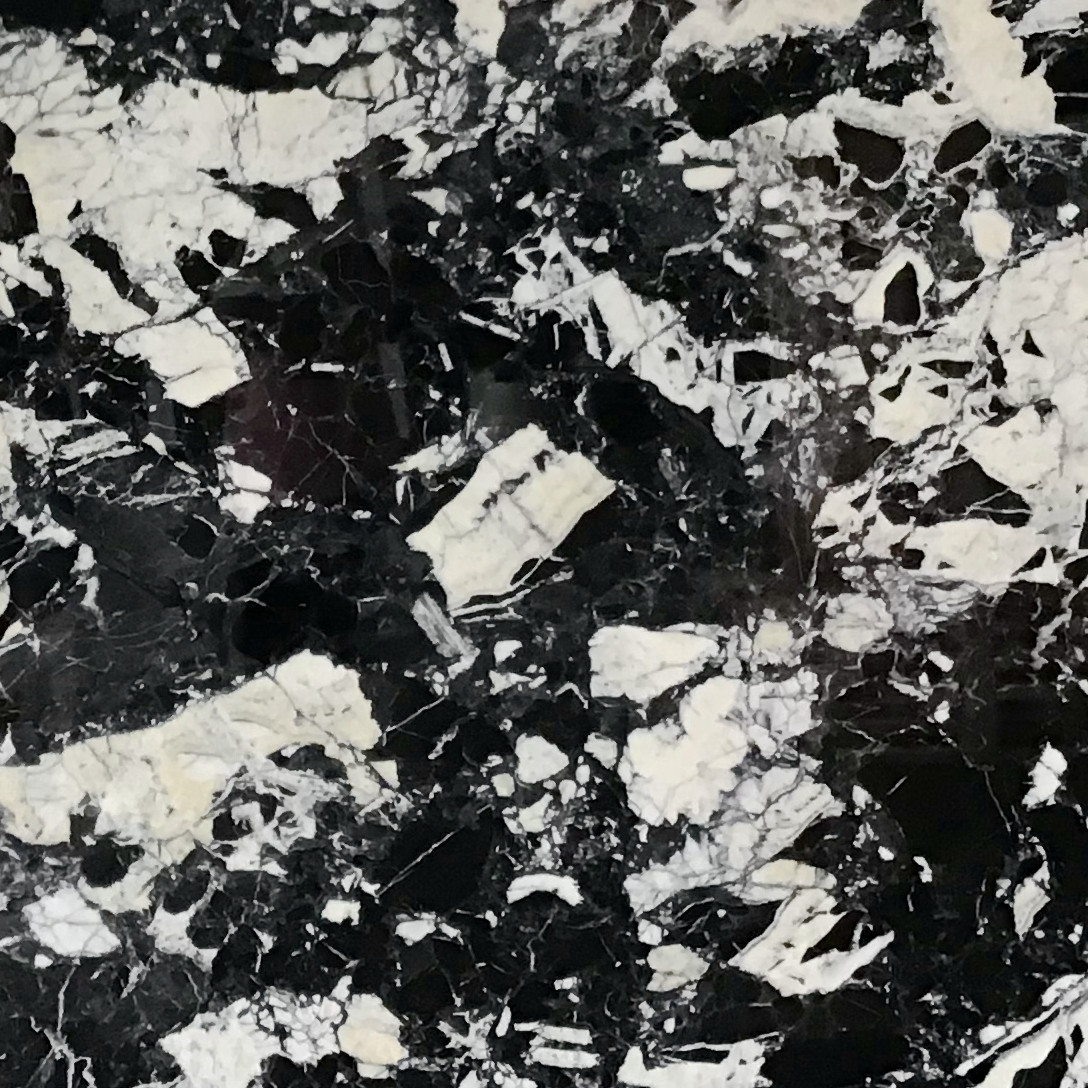

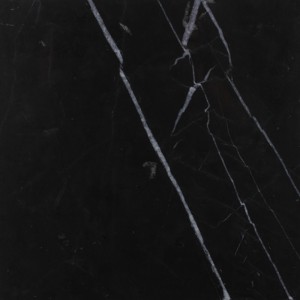

I-Classic Hot Sale Grand Antique Narural Black Marble

I-FAQ:

1. Kuyini ukucutshungulwa kokuqedwa kwama-slabs akho emvelo amatshe?

Ipholishiwe, ihlonishwe, igxiliwe, njll.

2. Yiziphi izinzuzo zakho?

Sinobudlelwano obuqinile nomnikazi wenkwali, ukuze sithole okubalulekile kuqala ukuze sikhethe amabhlogo angcono kakhulu anenani elincintisana kakhulu. Sithengise amabhulokhi amaningi amahle namakhulu e-Italy naseNdiya ngempendulo enhle.

3. Kunjani ukucutshungulwa kwakho kanye nephakheji?

Thina ICE STONE njalo sinake kakhulu izinga. Ngezansi isistimu yethu yokulawula ikhwalithi ukusuka kubhulokhi kuye ku-slab, bese kuba isevisi yokulayisha.

Okokuqala, sikhethe ibhulokhi kusuka ku-quarry ngqo. Singathembisa ibhulokhi ngayinye esiyithathayo ukuthi iyona nto engcono kakhulu. Okwesibili, sizohlanza amabhlogo esitokisini sethu futhi senze i-vacuum coating. Ngemuva kokwelashwa kwamabhulokhi, wonke amabhulokhi ethu azosikwa umshini wamasaha wezigelekeqe.

Bese uza esinyathelweni se-Back Net. Inetha elingemuva eline-resin efanele lingaqinisekisa ukuqiniswa nokuvalwa kwama-slabs. Ngemuva kwalokho, ukupholishwa kwe-slab kusetshenziswa i-epoxy resin yekhwalithi ephezulu eyenziwe ngabakwaTenax, e-Italy.

Ekugcineni, umhloli wethu wekhwalithi uzolandela zonke izinyathelo, futhi athinte ngokuqinile zonke izingcezu ze-slab ukuze aqinisekise ikhwalithi yokugcina yokupholisha. Uma i-slab ingakwazi ukuhlangabezana nezinga lethu, idinga ukupholishwa kabusha.

Isevisi Yokupakisha Efuthwayo Nesevisi Yokulayisha

Ngaphandle kokupholisha okuhle kwe-slab, iphakheji nayo ibalulekile. Ukwelashwa kokushisa nesitifiketi sokufuthwa yizici ezibalulekile. Lokhu kungathembisa ukuphepha kwezokuthutha. Ekugcineni, zonke izinyanda zizobe zimi kahle futhi zixhunywe enye kwenye ngokuya ngesibalo esiqondile.